COLLABARO SERVICES

Bespoke product application

Onboarding

Training

Support

Consultancy

Business Intelligence

RENEWABLES

GEV Wind Power are global market leaders in wind turbine blade maintenance services, delivering best in class with unrivalled expertise since 2015.

Founded in 2015 GEV have repaired tens of thousands of blades around the globe. Operating in over 25 countries they must navigate the coordination of over 500 technicians.

Challenge

Reports were being produced manually using laptops, written notepads and digital cameras. The process was not only time consuming and unreliable, but it was also frustrating for technicians as the size and number of images used in each report would invariably crash software like Microsoft Word which was not built for such large volumes of data. This meant longer lead times were needed to produce the necessary reports, which then required formatting and checking by project managers before they could be submitted to the client. The entire process from start to finish could take over two weeks.

Solution

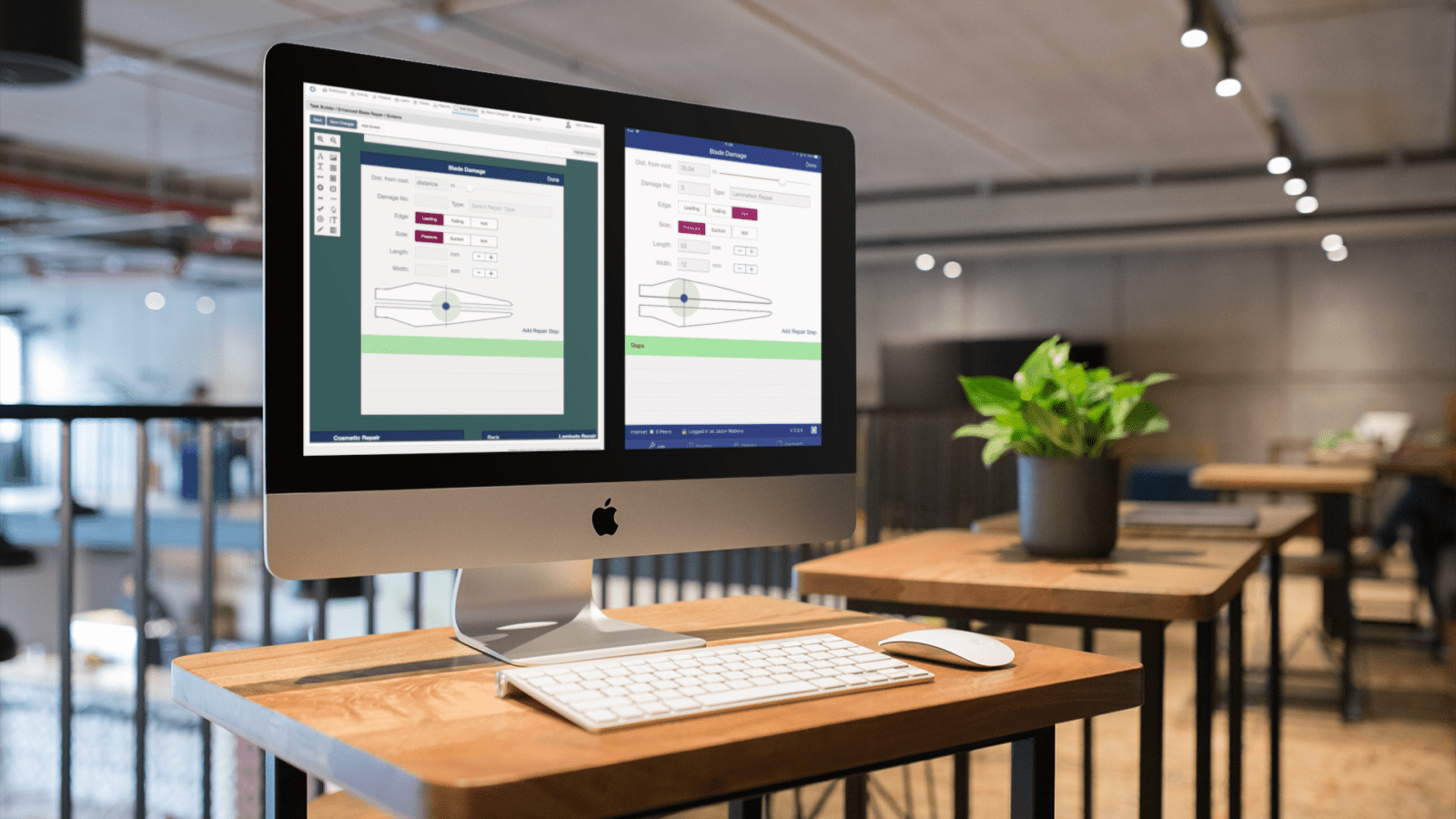

Railston & Co proposed an entirely new approach to the way technicians collected data. We removed the need for expensive laptops and cameras, replacing them with Apple Mini iPads (Wi‑Fi + Cellular). This enabled us to standardise the formatting and layout of each report, enabling the technician to capture all of the information required via the iPads. Data is now collected and saved centrally in the cloud instead of being buried in Word documents. This information can be turned into reports in a few seconds. Jobs and tasks can easily be broken down or created and sent to individual technicians in real-time. The Wi-Fi and Cellular sim allowed us to track the whereabouts and real-time status of the project down to the specific task a technician was working on. This data is then displayed in the operations centre on a digital map dashboard.